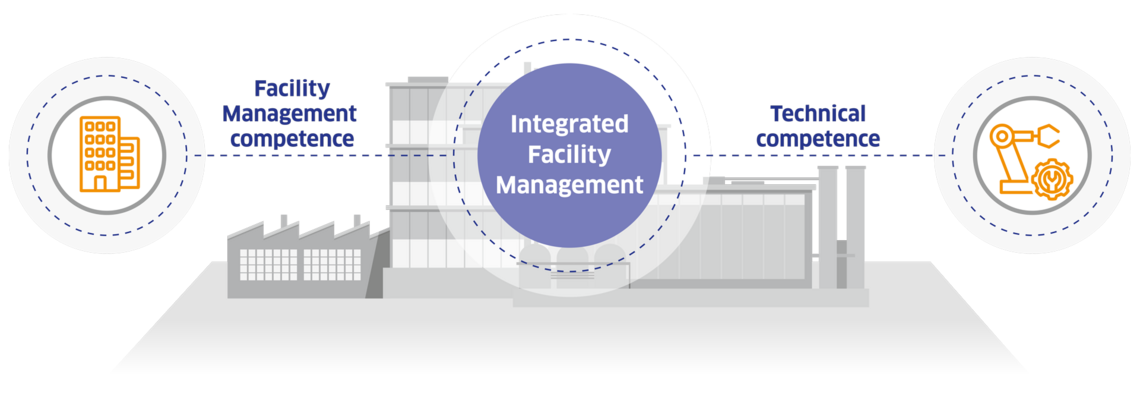

Integrated FM increases site productivity

The customers’ production facilities are where Leadec feels most at home and adds value. We have deep insights into factories at more than 350 locations and global blue-chip customers.

Leadec works by forming tailored Integrated Facility Management concepts that manage technical, infrastructural, and administrative processes equally. The objective of our solution is to optimize every stage in the process and the lifecycle of the assets & equipment.